As and when you have plans to install conduit electrical wires and cables in your home, garage shed, or barn, you first have to take a call on what type of wiring to be used for the chosen job. Certain types of wires may come enclosed with a sheath coating. This means that these can be fixed on the wall studs. Such kinds of electrical conduit NZ wires that are enclosed in the same sheath are risk-prone to damage if it comes in contact with anything sharp.

For such applications, the available option is using single strands of electrical wire that can be pulled in metal conduit. Single strands of wires thus attached with the conduit can add numerous wires from one electrical box to the other. However, you will have to choose the correct option for a specific application as per the National Electrical Code as electrical conduit nz come in different styles, from fairly strong construction to extremely rigid.

Conduits that are used to run electrical wiring in exposed locations in and around your home come in many types and their selection is application-specific. For your homes you could have a requirement of conduit to the inside of the walls to facilitate pulling additional circuits through the existing conduit runs at later times, choice of a conduit has to be specific to application.

Stranded or solid wires, either THHN or THWN are usually pulled through the conduit. The size of the conduit electrical wires chosen for a specific application may vary, depending on the amount of amperage needed to supply the point you are feeding, and this, in turn, determines the specifications of the conduit to be used.

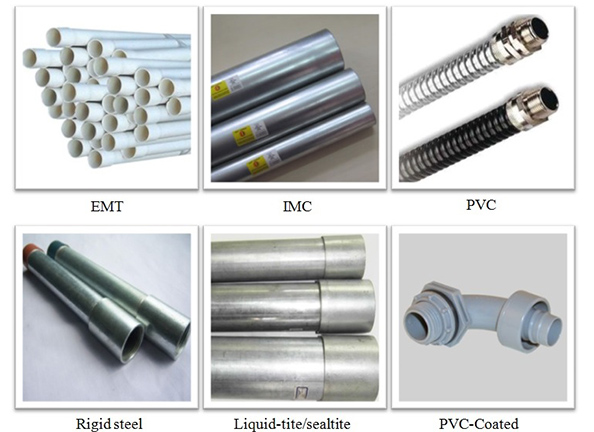

The electrical conduit NZ used for outdoor applications must be rated for that purpose. Different varieties of conduits in use are as follows:

- PVC conduit is preferred for underground and wet location applications. Such conduits are equipped with PVC fittings, connectors, couplings, and elbows since these are easy to attach with a cleaner and PVC glue. Moreover, the PVC conduit being non-conductive, these could be installed to run a green ground wire in the conduit for proper grounding methods at connection points.

- Flexible metal conduit is preferred to be used in areas that have restricted bends and limited space since it would be difficult to use regular conduits in such enclosed areas. Water heaters and attic vents are good examples of places where the flexible conduit installation can be most useful.

- EMT conduits are easy to carry, easy to bend, and can be installed within the walls. However, they are prone to easy damage, unlike IMC or rigid conduit.

- IMC conduit is galvanized and thicker that makes it a better choice for outdoor installations. Such conduits are also a good choice for exposed walls in basements, garages, outbuildings, and in those areas where the conduits are prone to damage easily.

- Rigid metal conduit, the most robust and heaviest of all conduit electrical wires can be used to run them under driveways and numerous other areas with extreme conditions. Rigid conduit threaded on the end is pricier as compared to other categories of conduits. Rigid conduits are the preferred choice of many utility companies since their use could ensure much better protection to the wiring and will also be able to withstand any natural condition including problems because of harsh wind, falling branches, and storm damage. Many applications require such electrical conduit Auckland to run through the roof for a safe and secure installation.